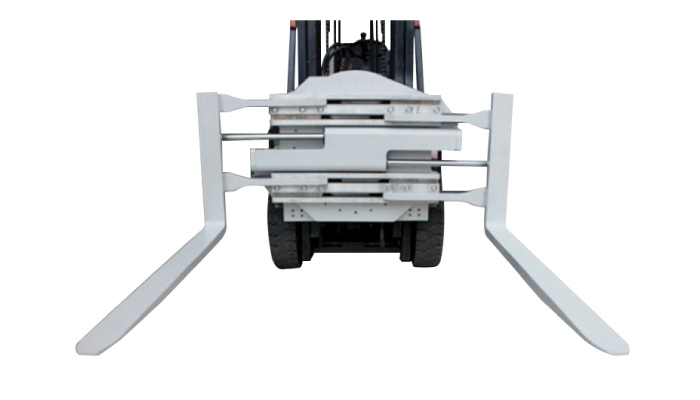

As pinzas de garfo pódense empregar para soster a mercadoría para realizar unha rotación continua de 360 graos e pódense usar para transferir a mercadoría da bandexa de produción de gama alta á bandexa de transporte máis barata. Pódense usar para transferir a mercadoría desde a gama alta. produción ata unha bandexa de transporte máis barata, aforrando así o custo da bandexa.

Vídeos

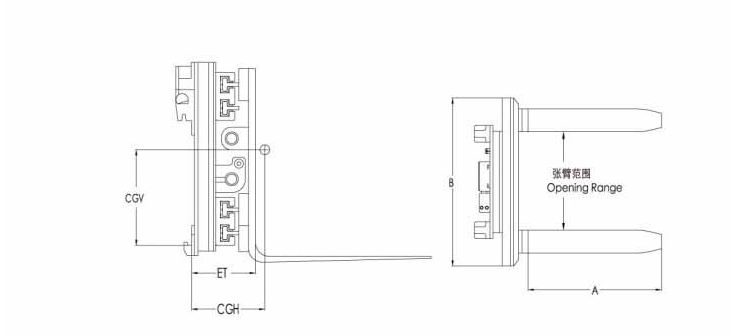

| Capacidade @ Centro de carga (kg @ mm) | Catálogo | Clase de montaxe | Apertura do rango (mm) | Lonxitude da tenedor (A) (mm) | Ancho do marco (mm) | Centro de Gravidade Vertical (CGV) (mm) | Centro de gravidade horizontal (CGH) (mm) | Grosor efectivo (ET) (mm) | Peso (mm) |

| 1600@600 | SLR-A601FR | 2 | 410-1660 | 1070 | 940 | 275 | 212 | 280 | 585 |

| 1600@600 | SLR-A602FR | 2 | 410-1660 | 1200 | 940 | 265 | 230 | 280 | 600 |

| 2300@600 | SLR-B602FR | 3 | 465-1800 | 1070 | 1015 | 270 | 345 | 345 | 696 |

| 2300@600 | SLR-B603FR | 3 | 465-1800 | 1220 | 1015 | 265 | 345 | 345 | 705 |

| 4000@600 | SLR-C604FR | 4 | 420-1960 | 1200 | 1300 | 362 | 320 | 320 | 1150 |

Nota

1) Obter a capacidade de carga completa de carretilla elevadora / accesorios da fábrica de empilhadeiras

2) Necesita unha empilhadeira para aumentar os 2 conxuntos de aceite de camiño.

3) O rango de apertura é a distancia entre o interior do garfo.

4) Os garfos poden basarse nas necesidades do usuario para instalar todo tipo de brazo de abrazadeira especial.

Detalles rápidos

Estado: Novo

Lugar de orixe: Fujian, China (continente)

Nome da marca: HUAMAI

Tipo: Paleteiro motorizado

Power Souce: AC Motor

Capacidade de carga nominal: 1600 kg

Máx. Altura de elevación: 1600mm

Mín. Altura de elevación: 1200mm

Lonxitude da tenedor: 1220 mm, 1070 mm

Ancho de tenedor: 150 mm

Dimensións totais: 2680x1225x2120mm

Certificación: ISO9001

Servizo posvenda: Non se presta servizo no exterior

Capacidade de carga: 1600 kg

Clase de montaxe: 2

Rango de apertura: 410-1660 mm

Ancho do marco: 940 mm

Grosor efectivo: 280 mm

Peso: 585 kg

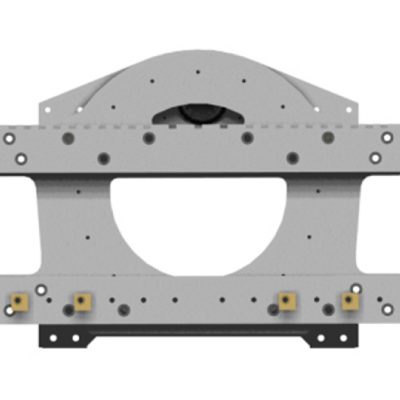

A Class 2 forklift attachment rotating fork clamp is a type of forklift accessory used for handling and transporting cylindrical loads such as drums, pipes, and rolls. The clamp attaches to the forklift and rotates 360 degrees, allowing the operator to easily pick up, move, and position the load.

The rotating fork clamp is designed to fit Class 2 forklifts, which are medium-duty forklifts typically used in manufacturing, construction, and warehousing. The clamp is attached to the forklift by a quick-release mechanism or by bolts, depending on the model. Once attached, the clamp can be easily raised and lowered by the forklift’s hydraulic system.

One of the main advantages of the rotating fork clamp is its versatility. It can handle a wide range of cylindrical loads, making it a convenient accessory for a variety of material handling tasks. The rotating feature also allows the operator to easily position the load in tight spaces or areas with limited access.

Another advantage of the rotating fork clamp is its ability to handle heavy loads. The clamp is designed to securely hold the load in place, reducing the risk of injury and damage to the load and the environment. The rotating feature also makes it easier to move the load in different directions, making it more efficient and cost-effective.

In conclusion, the Class 2 forklift attachment rotating fork clamp is a useful tool for handling and transporting cylindrical loads. It is versatile, efficient, and cost-effective, and is an essential tool for companies that handle heavy loads on a regular basis.