Vantaxes do produto

Unidade de carretilla elevadora de 3.0ton dividiu os equipos de pinzas de rolamento de papel de brazo longo con China Xinchai C490 motor, transmisión hidráulica, EUA EATON válvula de dirección asistida hidráulica, bomba de aceite SHIMADZU, chassis.It con suspensión completa é moi utilizada para entregar todo tipo de mercadorías, como palés, aceiro, ladrillo etc.Shantui colaborou con KOMATSU máis de 30 anos, todo o produto foi feito baixo o estándar KOMATSU.

Motor | Modelo | HUAMAI C490 | |

Saída nominal | 40/2650 | Kw / rpm | |

Par nominal | 165/1800 | N · m / rpm | |

Nº cilindro | 4 | ||

Altura × trazo | 90 × 105 | mm | |

Desprazamento | 2.7 | L | |

Dimensións | Altura de elevación | 3000 | mm |

LxWxH (con / sen tenedor) | 3779 (2709) x1226x2140 | mm | |

Radio de xiro | 2450 | mm | |

Ángulo de inclinación do mástil (F / R) | 6/12 | Titulación | |

Desempeño | Velocidade de viaxe (carga completa / sen carga) | 19/20 | Km / h |

Velocidade de elevación (con / sen) carga | 420/450 | mm / seg | |

Capacidade máxima | 20 | % | |

Peso propio | 4560 | Kg | |

Rodas e pneumáticos | Diante | 28 × 9-14-14PR | |

Traseiro | 6.50-10-10PR | ||

Ameaza de rodas | 1700 | mm | |

Despexe no terreo de xogo (mastro) | 110 | mm |

Vídeos

Detalles rápidos

Estado: Novo

Lugar de orixe: HUAMAI, China (continente)

Nome da marca: HUAMAI

Tipo: Paleteiro motorizado

Power Souce: Motor Diesel

Capacidade de carga nominal: 3000kg

Máx. Altura de elevación: 8000mm

Mín. Altura de elevación: 3000mm

Lonxitude da tenedor: 1070mm

Ancho de tenedor: 122 mm

Dimensións totais: 3829x1226x2140mm

Certificación: ISO9001 / ISO14001 / CE

Servizo posvenda: Enxeñeiros dispoñibles para maquinaria de servizo no exterior

Recursos: múltiples manipuladores de carga

Paper Roll clamps: China BRAND

Peso de accesorios: 650KGS

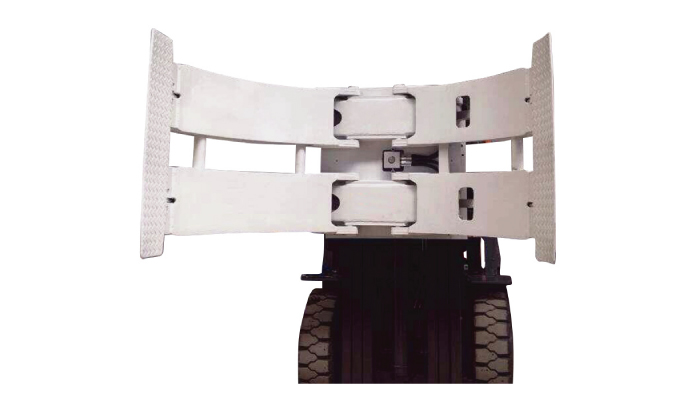

Rotación: 360 graos

CLASE DE MONTAXE: 3 etapas

Rango de rolos: 200-1300 mm

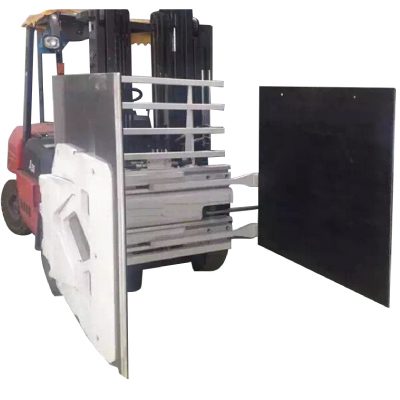

TIPOS: Brazo curto fixo

Tipo de almofada: opcional

Presión: 35-160ba

Capacidade de carga: 2ton

Split long arm paper roll clamps are specialized attachments used for handling and transporting large rolls of paper. They attach to a forklift and hold the rolls securely in place, allowing the operator to easily pick up, move, and place the rolls.

The split long arm paper roll clamps consist of two arms that attach to the forks of the forklift and a clamp mechanism in the center. The arms are designed to split apart, making it easier to place the rolls in the desired position. The clamp mechanism is designed to securely hold the rolls in place, reducing the risk of injury and damage to the load and the environment.

One of the main advantages of the split long arm paper roll clamps is their versatility. They can handle a wide range of large rolls of paper, making them a convenient accessory for a variety of material handling tasks. The split arms also make it easier to transport the rolls, reducing the risk of injury to the operator and other workers.

Another advantage of the split long arm paper roll clamps is their efficiency. They make it easier to handle and transport the rolls, reducing the time and effort required to complete the task. This makes them more cost-effective and time-efficient, saving companies time and money in the long run.

In conclusion, split long arm paper roll clamps are a useful tool for handling and transporting large rolls of paper. They are versatile, efficient, and cost-effective, and are an essential tool for companies that handle heavy loads on a regular basis.